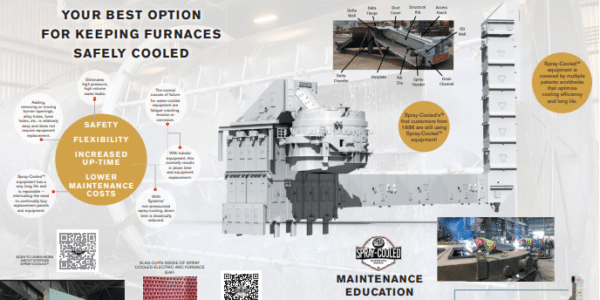

Lower Maintenance Costs

Constructed from readily available and easily workable thin, carbon steel plate, Systems Spray-Cooled equipment reduces the furnace maintenance costs associated with water-cooled components in a SAFER, more accessible, and maintenance-friendly manner.

- Multiple, custom-sized, and located access ports provide free access to the spray system and water or “wet” side of the hot face for routine inspections and repairs.

- Thin wall, carbon steel plate construction eases repair procedures and the time required for repairs is reduced.

- Quick and easy “Weld-A-Patch” techniques eliminate the need to take equipment offline for most minor to moderate repairs, thus reducing costly downtime.

- One-piece construction eliminates panel-to-panel jumper hoses and valves, and the time required to remove and reinstall with each panel replacement.

- Because the thin carbon steel plate hot face is the only “wear” item, Spray-Cooled™ components can easily be rebuilt at a fraction of the cost of replacement.

- At a typical weight of less than half that of alternative equipment, Spray-Cooled™ equipment reduces the wear and tear on turret arms, rotating bearings, and other peripheral components.

- Smooth plate construction of Spray-Cooled™ equipment provides longer life by reducing the inherent erosion-corrosion attack between pipe interstices associated with tubular-type construction.

Video

Watch three ways that Systems Spray-Cooled equipment can lower your furnace maintenance costs through erosion/corrosion reduction, weight, and construction.

Improving furnace reliability while decreasing and easing maintenance requirements, providing Safer working conditions in a cleaner environment, reducing the cost of spare parts inventories while extending the service life of the equipment, and providing for more production with less energy, Systems Spray-Cooled equipment is “Staying Cool in a Hot Business.”