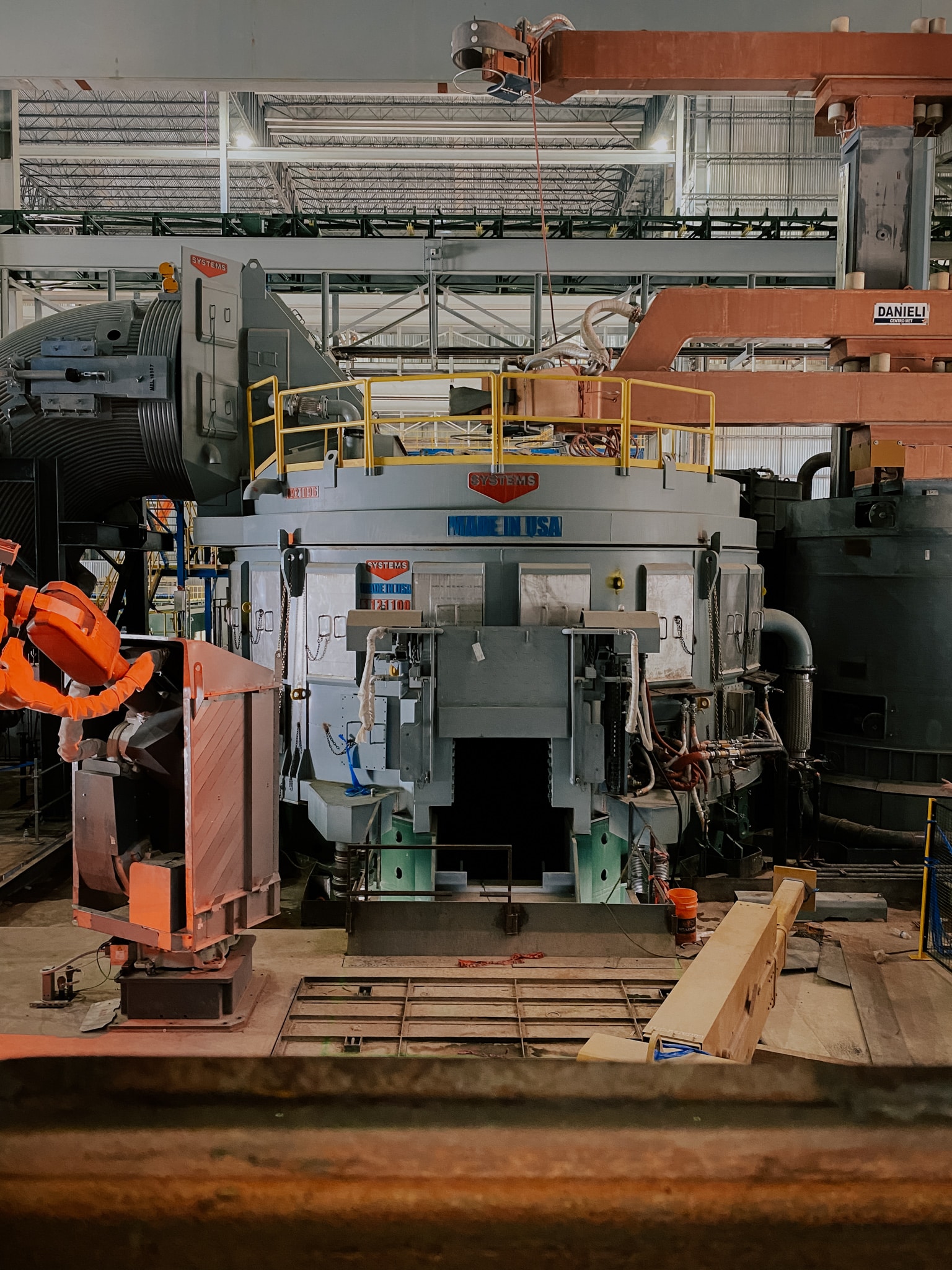

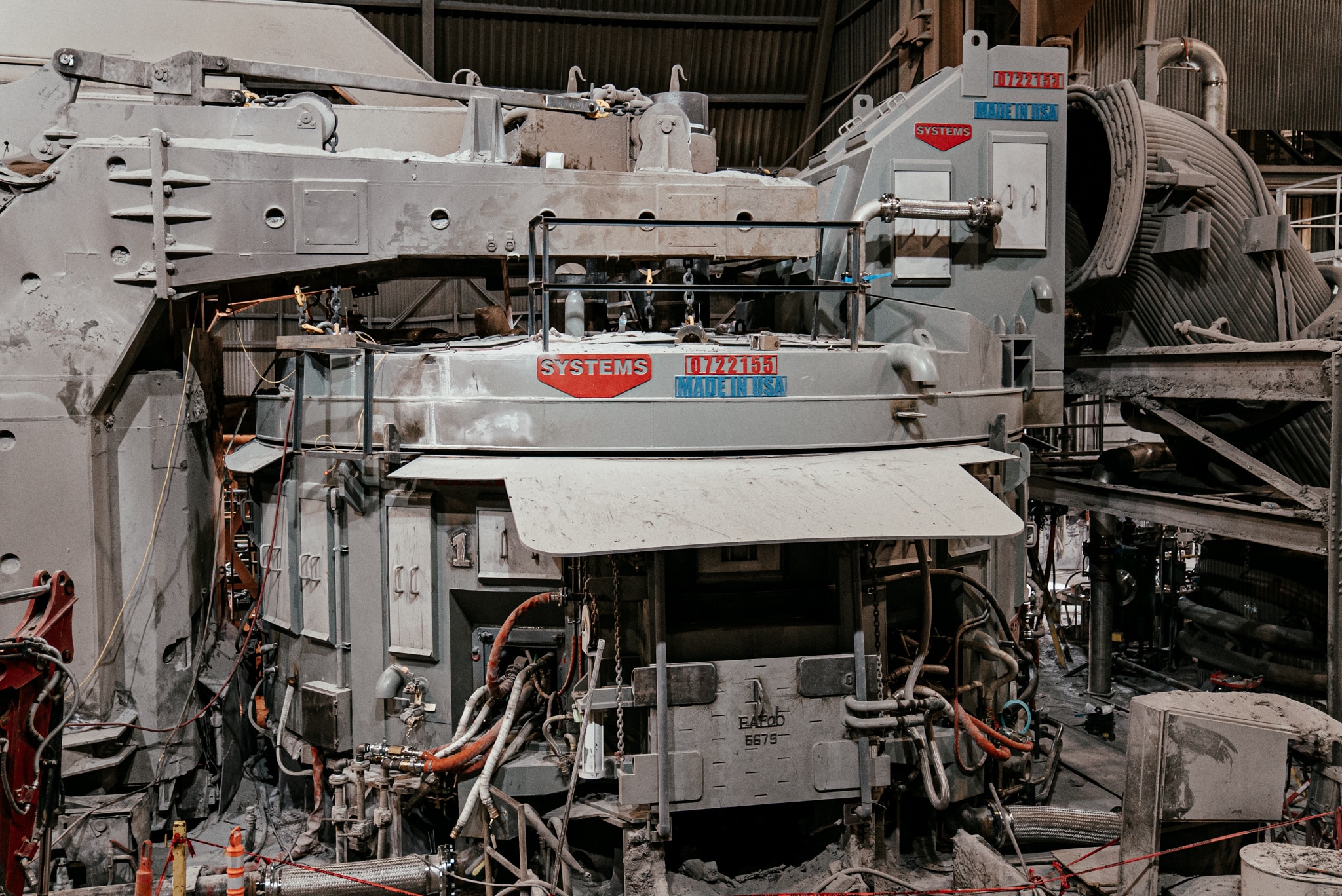

Key Spray-Cooled™ Projects

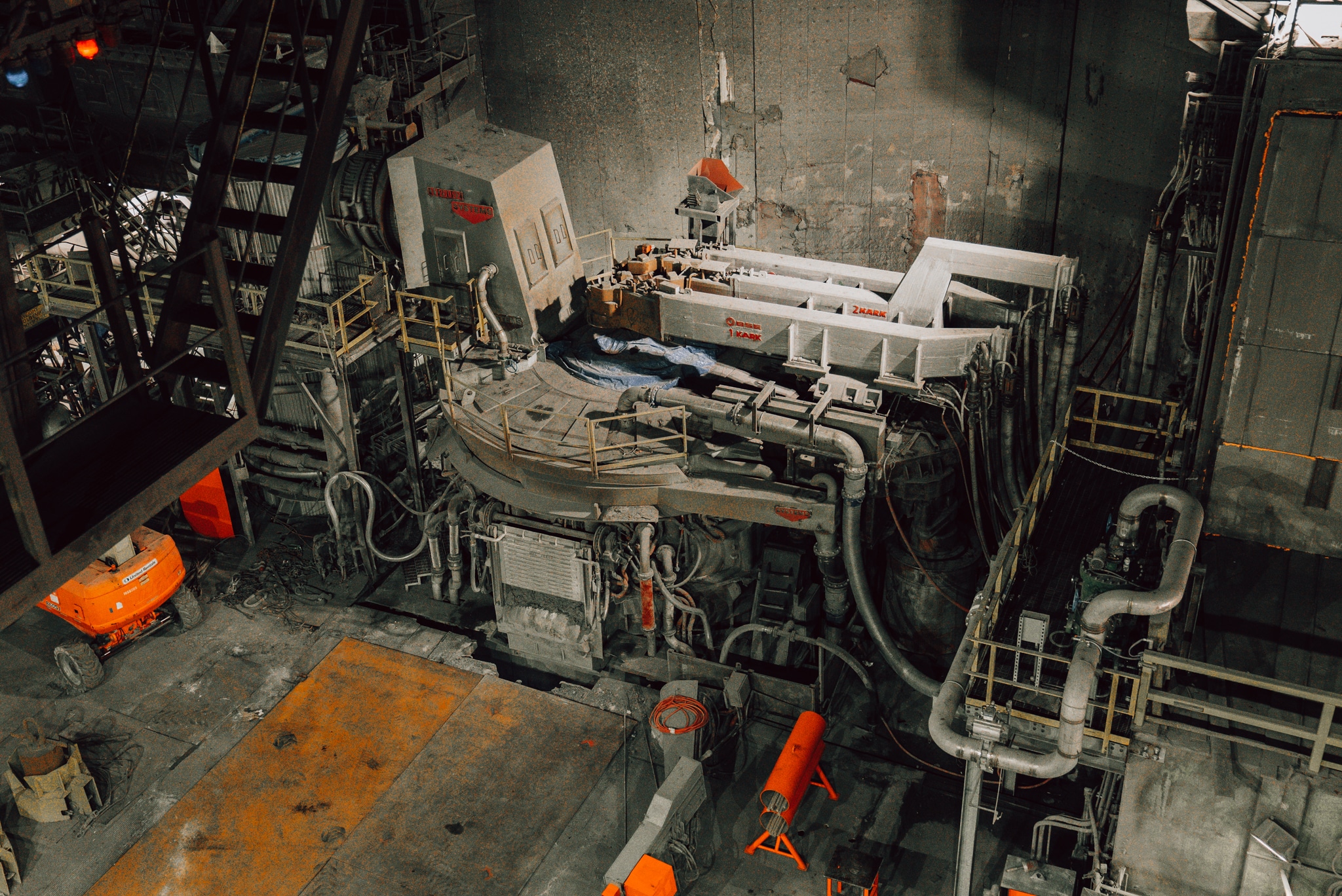

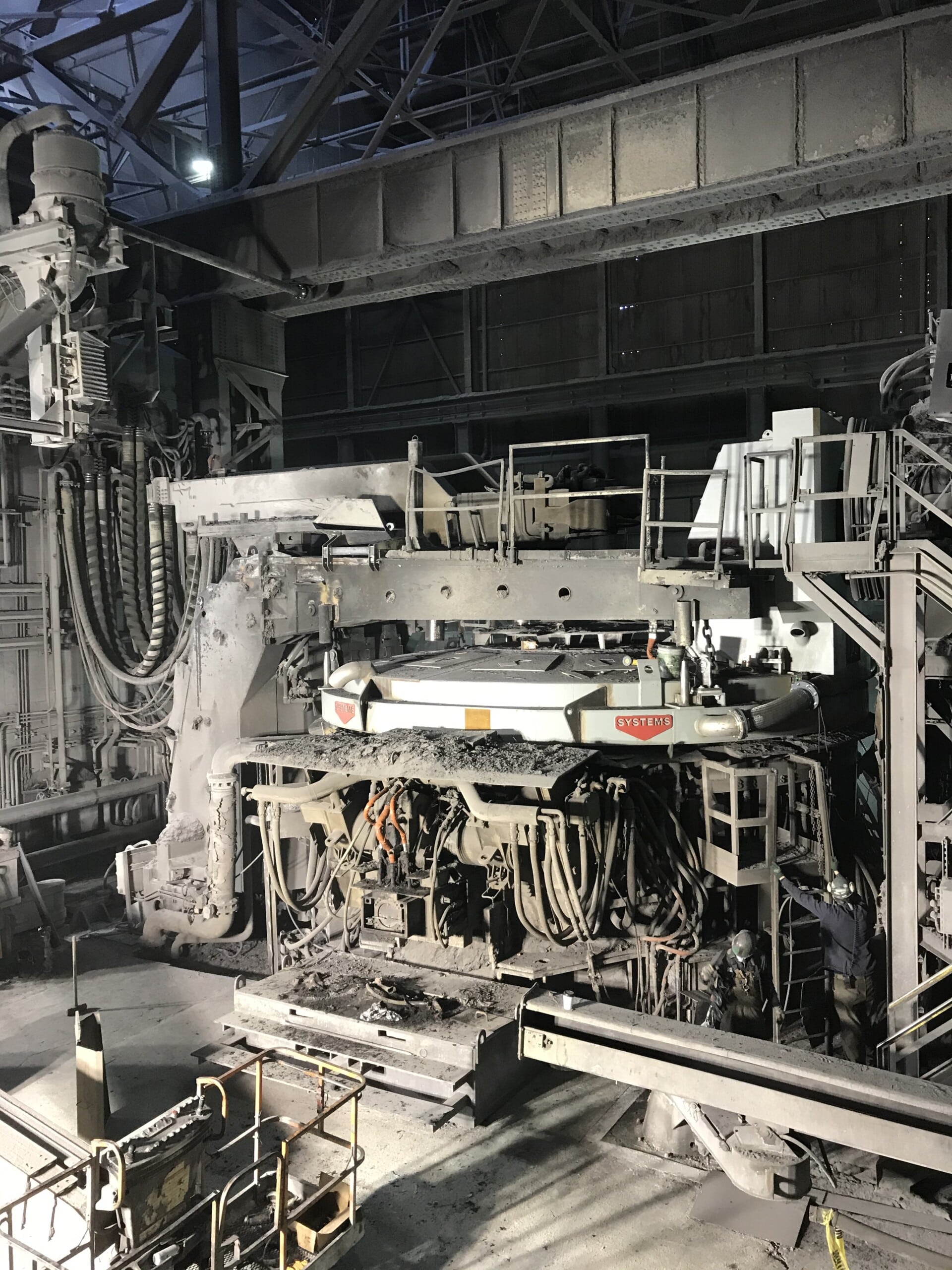

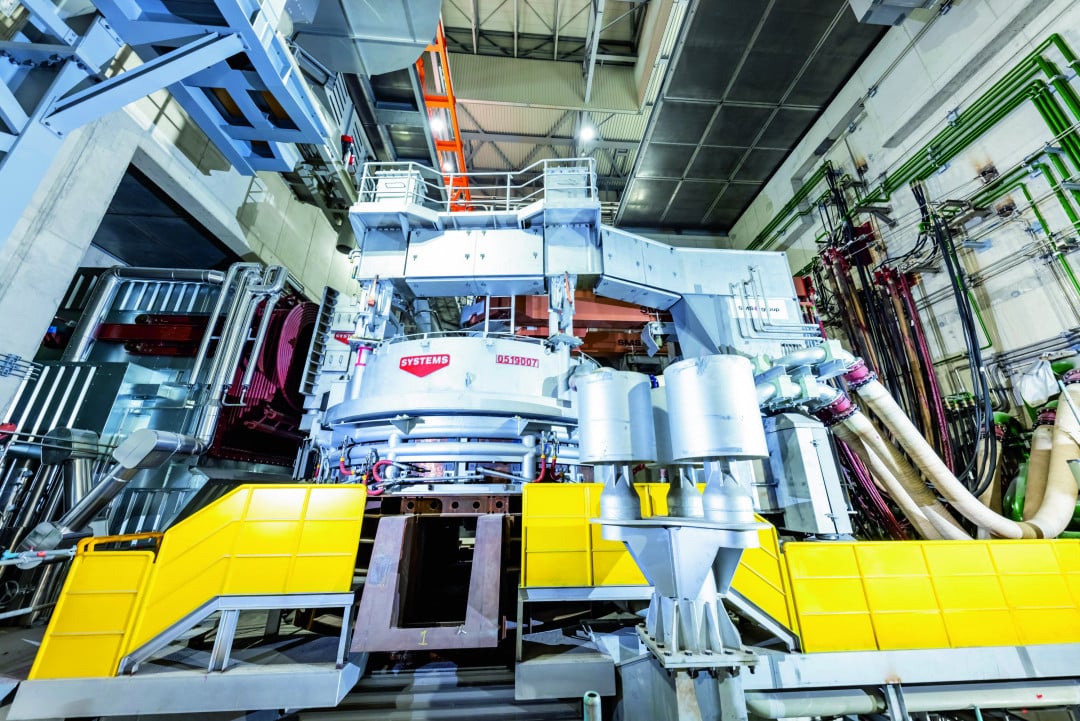

With our experienced team of Engineers and Designers, Systems Spray-Cooled can handle any sized project from a single piece of equipment conversion to an entire melt shop of equipment and off-gas ducting. We have the facilities and experience to handle any project our customers need.

Some of our recent large-scale projects include:

- Complete melt shop equipment (sidewalls, roofs and elbows for a 26’-4” dia furnace) and off-gas ducting (approximately 180’ of 10’ dia duct including a 13’-4” x 19’-11” x 23’-10” tall panelized dropout chamber) for two identical furnaces at Steel Dynamics in Columbus, MS (formerly Severstal)

- Sidewalls and roofs for two 24’-4” dia furnaces, including two 15’-4” x 15’-4” dropout chamber roofs, for Nucor-Yamato Steel in Blytheville, AR

- Replacement 11’-7” x 14’-7” x 37’-9” tall panelized Consteel off-gas doghouse duct for Nucor Steel in Cofield, NC

- Roofs and elbows for a 24’-7” dia. twin-shell furnace at Nucor Steel in Tuscaloosa, AL

- Sidewalls and roofs for two 22’-4” dia. Furnaces at Nucor Steel in Crawfordsville, IN

- Sidewalls and roofs with integrated elbows for a 26’-4” furnace for Big River Steel in Osceola, AR

- Roofs and elbows for a 20-10” dia. furnace for Nucor Steel in Kankakee, IL

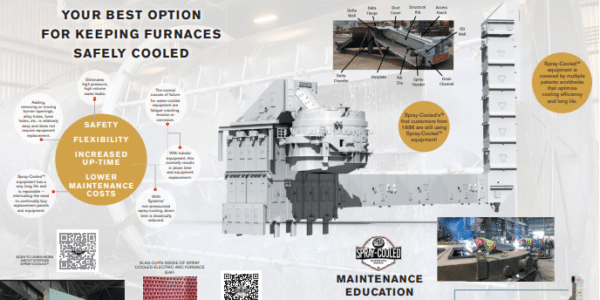

Spray-Cooled™ Capabilities Brochure

Overview of Systems Spray-Cooled, our division that supplies furnace water-cooling systems for melt shops and steel mills, primarily electric arc furnaces. Learn how Spray-Cooled™ technology decreases furnace maintenance costs while increasing reliability and safety.

Spray-Cooled™ Capabilities Video

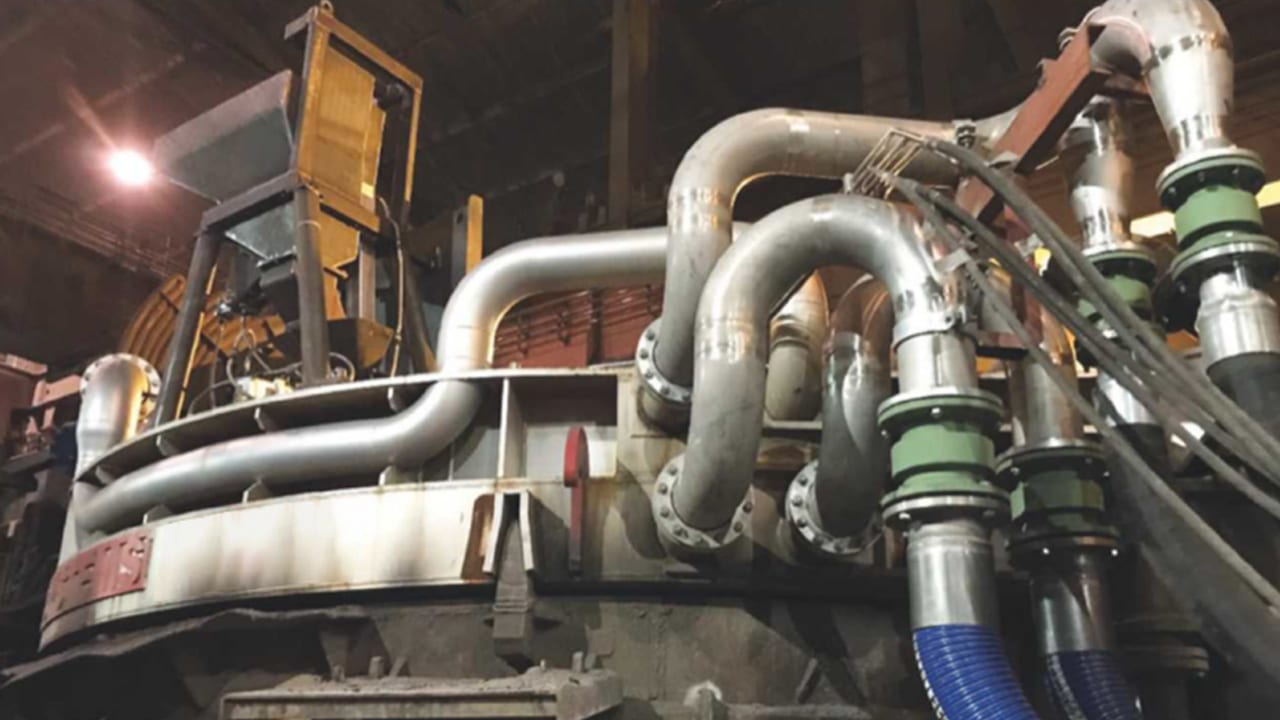

Serving the global metals and minerals industries, Systems’ patented Spray-Cooled™ Technology provides a safer, greener alternative to conventional pressurized water-cooled, exotic alloy, and refractory equipment for extreme heat load applications.

Using non-pressurized, non-evaporative water-cooling, Systems Spray-Cooled offers a complete line of electric arc furnace (EAF), ladle metallurgical furnace (LMF), basic oxygen furnace (BOF), submerged arc furnace, post combustion, and dust evacuation system components.