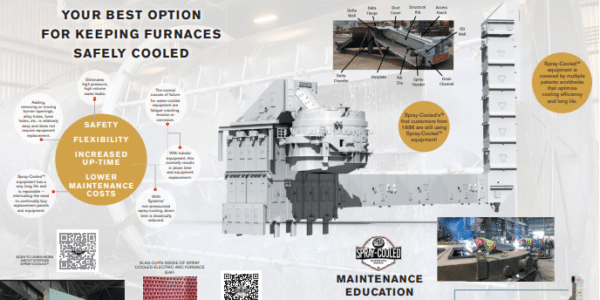

Smelting Furnace Roofs

Equipment reliability, accessibility, leak detection and monitoring, and in-situ repairability were primary objectives during the development of Systems Spray-Cooled panelized furnace roofs. All of these objectives were achieved and the campaign goals were established at 5 years!

All of the many technological, safety, environmental, operational, and maintenance benefits of our Spray-Cooled™ equipment can be found on Systems Spray-Cooled panelized furnace roofs, and years of successful operation have proven the viability, economy, and reliability of our technology in this most demanding of smelting industry applications.

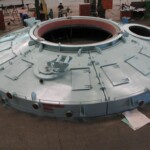

- Large-diameter furnace roofs can be panelized into “pie slice” panels with radial panel gaps. Each panel is completely self-sustaining with independent cooling water supply, distribution, and drainage.

- Light weight minimizes lifting and smelting equipment support peripherals.

- Tension-ring structural concept facilitates single-panel removal.

- Dual containment capabilities facilitate leak detection monitoring.

- The hot face and entire cooling water system are accessible and repairable from the outside, in situ.

- Safer smelting operations

- No special chemical treatment of the cooling water is required for Systems Spray-Cooled panelized smelting furnace roofs.

EAF Steep Cone Roof Video