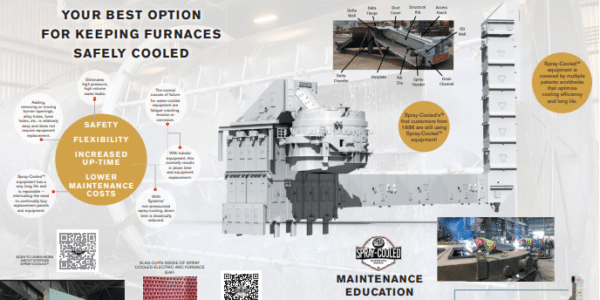

Electric Arc Furnace

Off-Gas Ductwork

All of the many technological, safety, environmental, operational and maintenance benefits of our Spray-Cooled™ equipment are recognized in Systems Spray-Cooled off-gas ductwork. One-piece construction and dual containment capabilities make our ductwork the GREENEST choice available.

- One-piece construction and continuous plate hot face eliminates potential air gaps thus reducing gas exfiltration into the environment and ambient air infiltration.

- Containment cover provides means for dual containment and gas leak monitoring and detection.

- Efficient cooling method provides for more direct application of cooling in areas of need without increasing total cooling water flow requirements.

- Multiple access ports provide means to perform routine inspections and repairs from outside.

- The thin carbon steel plate, hot face, is the only wear item in the duct, thus facilitating “Rebuild versus Replace“ procedures for dramatic long-range cost savings.

- Ability to extend the service life of the hot face by decreasing thickness where thermal stresses are controlling, and increase the thickness as an allowance where erosion/corrosion conditions are controlling the life.

- Smooth surface in contact with the gas stream decreases the build-up of dust, which can lead to corrosion and reduced heat transfer.

- Continuous plate hot face eliminates degradation of gas stream containment over the life of the duct.