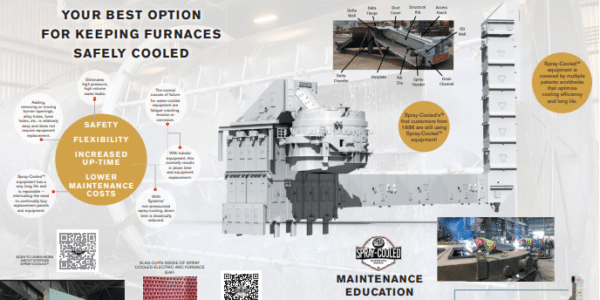

Sytems Spray-Cooled technology is a Better Alternative to Exotic Alloy Components

By atomizing a water stream, the surface area of the cooling media is instantaneously and dramatically increased, thereby increasing the cooling efficiency of Spray-Cooling™ over other conventional stream and evaporative water-cooling methods. The increased cooling efficiency combined with our patented products, patented and proprietary methods of application, and slag enhancement products and methods allow most heat loads encountered to be within the acceptable limits of transfer through conventional, thin, carbon steel plate materials. Not only is this desirable from an initial investment cost standpoint, but the ease of routine maintenance and repairs of carbon steel plate is much preferable over copper, bronze, aluminum bronze, and other exotic alloy materials used to help protect the equipment in other less efficient cooling technologies.

For those areas where alternative materials may be desired such as burner blocks and hot spot panel inserts, Systems Spray-Cooled has successfully incorporated many different materials within our Spray-Cooled™ furnace components.