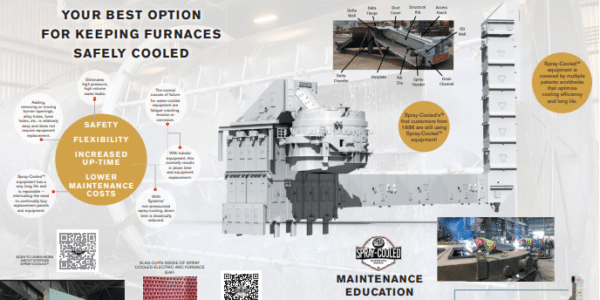

Systems Spray-Cooled technology is a SAFER Alternative to Pressurized Water-Cooled Furnace Systems

- Operating at atmospheric pressure, Spray-Cooling™ eliminates the potential for high-pressure, high-volume water leaks.

- The entire hot face of every Spray-Cooled™ component is accessible from the “wet” side so that inspections and repairs may be accomplished without exposure to the “hot” side of the furnace equipment.

Why We’re the Better Alternative Video

Systems Spray-Cooled technology provides superior ENVIRONMENTAL Performance to Pressurized Water-Cooled Furnace Systems

- The one-piece construction of Systems Spray-Cooled equipment eliminates panel-to-panel gaps as well as tube-to-tube gaps, thus minimizing flame and fume emissions as well as air infiltration, keeping your steel mill melt shop cleaner and cooler.

- Secondary containment of Spray-Cooled™ equipment facilitates gas/fume leak detection and monitoring.

Systems Spray-Cooled technology is a MORE ENERGY EFFICIENT Alternative to Pressurized Water-Cooled Furnace Systems

- The enhanced cooling methods and slag retention procedures and products incorporated into our Spray-Cooled™ equipment, retain more energy in the furnace, thus reducing the energy losses to the environment and to the water system.

- Operating at lower cooling water supply pressures, and at atmospheric drain pressures greatly reduces the pumping energy required of the steel mill utility system.

- Minimizing air infiltration into the furnace and gas stream facilitates better post-combustion control.

Systems Spray-Cooled technology is a MORE COST EFFICIENT Alternative to Pressurized Water-Cooled Furnace Systems

- Better thermal stress management, better and more readily applicable repair procedures, and a SAFER component all help provide a longer service life for Spray-Cooled™ equipment than for pressurized water-cooled furnace equipment.

- “Rebuild versus Replace” campaigns provide long-term cost savings for steel mills.

We Are the Better Alternative

Systems Spray-Cooled furnace equipment is a cut above pressurized water cooling. It provides Safer operations, superior environmental performance, and more efficiency in both energy and cost.

Applications include electric arc furnace roofs, sidewalls/shells, roof elbows, off-gas ductwork, LMF roofs, BOF hoods, smelting furnace roofs, and panelized applications.