Mining / Ore Smelting Industry

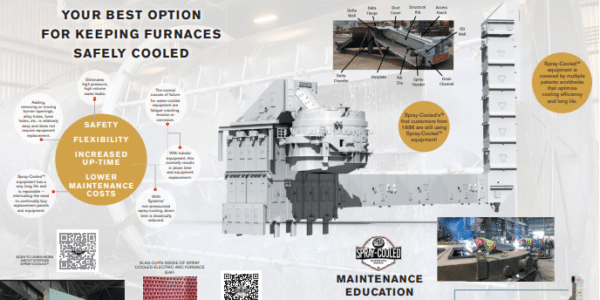

Operational reliability in helping to achieve long-term closed campaigns on the large diameter, submerged arc furnaces of the ore smelting industry have made Systems Spray-Cooled technology the Leader in the field of water-cooled furnace roofs, chimneys, and off-gas duct.

The additional SAFETY and Environmental Benefits provided by our Spray-Cooled™ technology combined with the enhanced slag retention system, natural scrubbing action of the efficient cooling methods, the maintainability from outside, and the inherent monitoring-friendly designs have led to the development and successful implementation of the following iron ore smelting applications:

- Free Standing, Panelized Smelter Furnace Roofs

- AC Furnaces

- DC Furnaces

- Steep Cone EAF Roofs (High Profile)

- Shallow Cone EAF Roofs (Low Profile)

- Chimneys

- Off-Gas Stacks

- Off-Gas Duct

- Paddy Elbows

EAF Steep Cone Roof Video

Improving smelter furnace reliability while decreasing and easing maintenance requirements, providing safer working conditions in a cleaner environment, reducing the cost of spare parts inventories while extending the service life of the ore smelting equipment, and providing for more production with less energy – Systems Spray-Cooled equipment is “Staying Cool in a Hot Business”.