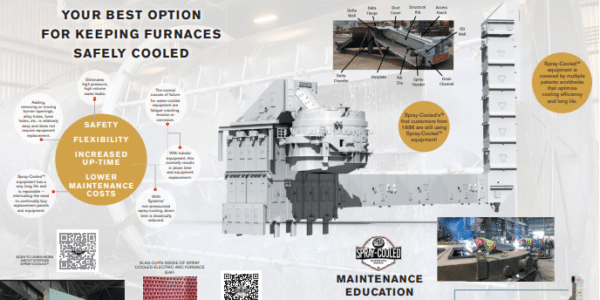

Furnace Water-Cooling: The Safer Alternative

As the only non-pressurized water-cooled alternative, Systems Spray-Cooled equipment is the SAFER alternative to conventional furnace water-cooling. Because Spray-Cooled™ equipment operates at atmospheric pressure, the cooling water is not pumped across the area to be cooled. Therefore the potential for high-pressure, high-volume water leaks is eliminated. Positive extraction of the spent cooling water further reduces the amount of water present within the equipment. Furthermore, by nature of its design, Systems Spray-Cooled equipment provides a means for accessing the hot face from the “wet” side of the plate. This provides much SAFER inspection and repair from above and eliminates the need to access the hot face from the “hot” side.

Safer Alternative Video

By relying upon water drop impingement cooling at atmospheric pressure rather than stream cooling or evaporative cooling, the Spray-Cooled™ technology provides all the benefits of water-cooling at a greater efficiency than conventional furnace water-cooling methods and in a design that provides a much SAFER operating and maintenance environment in your shop.

Spray-Cooled™ equipment’s One-Piece design minimizes flame and fume emissions. This also reduces air infiltration and improves gas handling efficiency. This makes your shop and operating environment cleaner.

By nature of its design and construction, Spray-Cooled™ equipment has an indefinite life. The readily available carbon steel hot face is the only “wear” item in its construction. Upon reaching the cyclic life of the hot face, it is not necessary to replace the entire piece of equipment but simply rebuild the wear item, and the Spray-Cooled™ component is as good as new.

Improving furnace reliability while decreasing and easing maintenance requirements, providing safer working conditions in a cleaner environment, reducing the cost of spare parts inventories while extending the service life of the equipment, and providing for more production with less energy – Systems Spray-Cooled furnace water-cooling equipment is “Staying Cool in a Hot Business”.