Iron & Steel Foundry Works Industry

With today’s growing demands for production, increased energy input has added to the demands of the furnace vessel. Typical heat loads have taxed the abilities of conventional cast and brick refractories in iron and steel foundries to continue to offer an economically viable solution. Systems Spray-Cooled EAF components have proven to provide the answer for those willing to ask the question. Spray-Cooled™ equipment’s one-piece construction and enhanced slag retention systems provide a similarly “closed” furnace system with typically less than half the weight and typically 5 times the life. Additionally, at the end of the useful life cycle of the wear face, a simple re-lining of the thin carbon steel plate hot face will make the equipment like new again.

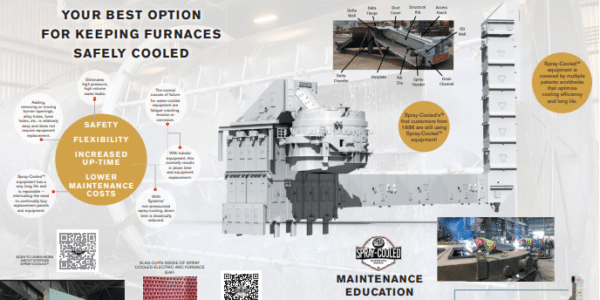

Spray-Cooled™ Capabilities Brochure

Overview of Systems Spray-Cooled, our division that supplies furnace water-cooling systems for the iron and steel foundry works industry, primarily electric arc furnaces. Learn how Spray-Cooled™ technology decreases furnace maintenance costs while increasing reliability.

What if there was a way…

Not only can Systems Spray-Cooled benefit ultra high powered EAF furnaces but it can also benefit foundry furnaces. Contact Systems Spray-Cooled today to find out how your foundry can lower cost and operate safer.

Improving furnace reliability while decreasing and easing maintenance requirements, providing Safer working conditions in a cleaner environment, reducing the cost of spare parts inventories while extending the service life of the equipment, and providing for more production with less energy – Systems Spray-Cooled equipment is “Staying Cool in a Hot Business”.