Within the steelmaking furnace vessel, slag is a valuable, free insulator that if utilized and maintained properly can serve to prolong the life of the containment equipment as well as to serve to retain energy within the furnace. However, the violent and unpredictable nature of the electric arc, on occasion creates “hot spots” that tend to melt even the best planned slag coverage. Because the instantaneous heat load present during such an event is so high as to melt the slag coverage, the containment equipment is exposed and vulnerable to an arc spiked load.

In order to account for these “hot spots” within the furnace vessel, SYSTEMS Spray-Cooled™ engineers have developed our patented Copper Slag Retainers. By recognizing the heat transfer rate of copper as being approximately 10X that of the surrounding carbon steel, and by transferring the heat in a direct path to the cooling water, we have found that our Copper Slag Retainers, when working in conjunction with our enhanced slag retention system, are able to freeze the slag in most “hot spots”, thus maintaining the protection and preventing energy losses.

Safer Alternative Video

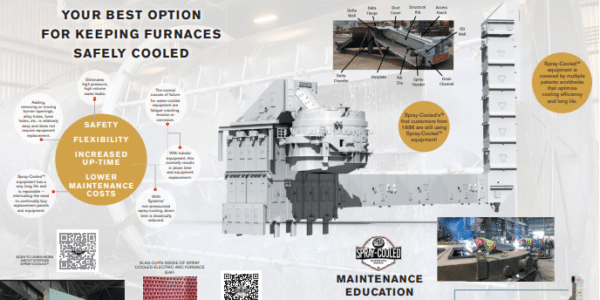

Improving furnace reliability while decreasing and easing maintenance requirements, providing safer working conditions in a cleaner environment, reducing the cost of spare parts inventories while extending the service life of the equipment, and providing for more production with less energy – SYSTEMS Spray-Cooled™ equipment is “Staying Cool in a Hot Business”.