Developed by electric arc furnace operations and maintenance personnel for their own use, Systems Spray-Cooled EAF roofs provide all of the benefits of water-cooling in a Safer, more reliable, less troublesome, and more energy-efficient manner.

Systems Spray-Cooled EAF upper shells/sidewalls provide the Safer alternative to pressurized water-cooled panels.

All of the many technological, Safety, environmental, operational, and maintenance benefits of our Spray-Cooled™ equipment are recognized in Systems Spray-Cooled EAF roof elbows.

All of the many technological, Safety, environmental, operational, and maintenance benefits of our Spray-Cooled™ equipment are recognized in Systems Spray-Cooled off-gas ductwork.

Many aspects of the design and construction of Systems Spray-Cooled equipment demonstrate inherent advantages. One case in point is the application of our Spray-Cooled™ technology to the LMF roof.

The extreme heat loads created during oxygen blow, the detrimental erosion and corrosion conditions present, and the grave difficulties of repair and replacement were all significant considerations in deciding to develop the Systems Spray-Cooled BOF hood.

Equipment reliability, accessibility, leak detection and monitoring, and in-situ repairability were primary objectives during the development of the Systems Spray-Cooled panelized smelting furnace roof.

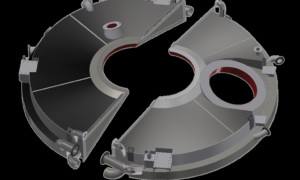

One predominate advantage of Systems Spray-Cooled equipment is the ability to create large, integrated, one-piece constructions of equipment that heretofore was panelized.

Developed by electric arc furnace operations and maintenance personnel for their own use, Systems Spray-Cooled EAF roofs provide all the benefits of water-cooling in a Safer, more reliable, less troublesome, and more energy-efficient manner.