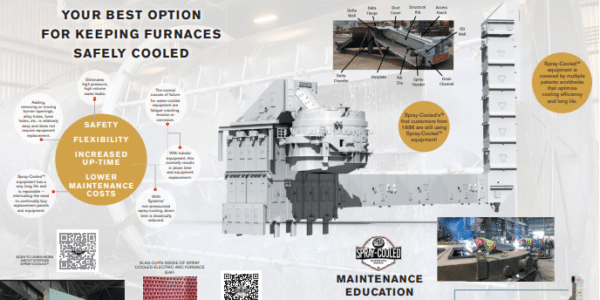

Systems Spray-Cooled technology is a Better Alternative to Conventional Furnace Refractory Material Components

- Because of its inherent flexibility, the steel plate hot face of a Spray-Cooled™ component develops much less stress over time than the rigid furnace refractory components.

- The SAFER form of water-cooling provided by Systems Spray-Cooled equipment significantly reduces the safety concerns held by those resistant to converting from steel furnace refractory components to water-cooled components.

- Our Spray-Cooled™ technology eliminates the frequent dependence upon outside services to supply refractory castables.

- Systems Spray-Cooled equipment provides a dramatic increase in service life over conventional furnace refractory material components for steel mills.

- The lighter weight of Spray-Cooled™ equipment extends the life of ancillary lifting and manipulating shop equipment, lifting gantry, turret and turret bearings, shop cranes, etc.

Issues with Conventional Furnace Refractory Materials

Conventional furnace refractory materials, such as firebricks and castables, often face several issues that compromise their efficiency and longevity. One of the primary problems is their susceptibility to thermal shock, which results from rapid temperature changes. This causes cracks and structural degradation over time, leading to higher maintenance costs and shorter operational lifespans. In contrast, the steel plate hot face of a Spray-Cooled™ component is structurally flexible, developing much less long-term stress.

Additionally, these materials may not withstand the highly corrosive environments of modern furnaces, especially when exposed to slag, molten metals, or acidic compounds, which accelerates wear. Because Spray-Cooled™ components are free of any refractory materials, corrosive concerns are greatly reduced.

Also, traditional refractories are relatively dense, adding to the overall weight of the furnace, which can complicate design and installation. Because Spray-Cooled™ equipment is lighter, these aspects are simplified. Further, ancillary lifting and manipulating shop equipment life is extended due to far less load.

Considering expenses, a smaller foundry roof with refractory materials has to be replaced every 1-2 weeks. The same-sized Spray-Cooled™ roof will last at least 12-18 months. Conversion costs aside, a 4-6 month return on investment can be expected.